Funny how a machine gets bigger when you move it to a smaller yard…

The vacuum reservoir for the Hydrovac was pitted through. A chopped fire extinguisher canister was the right diameter and only required one additional port.

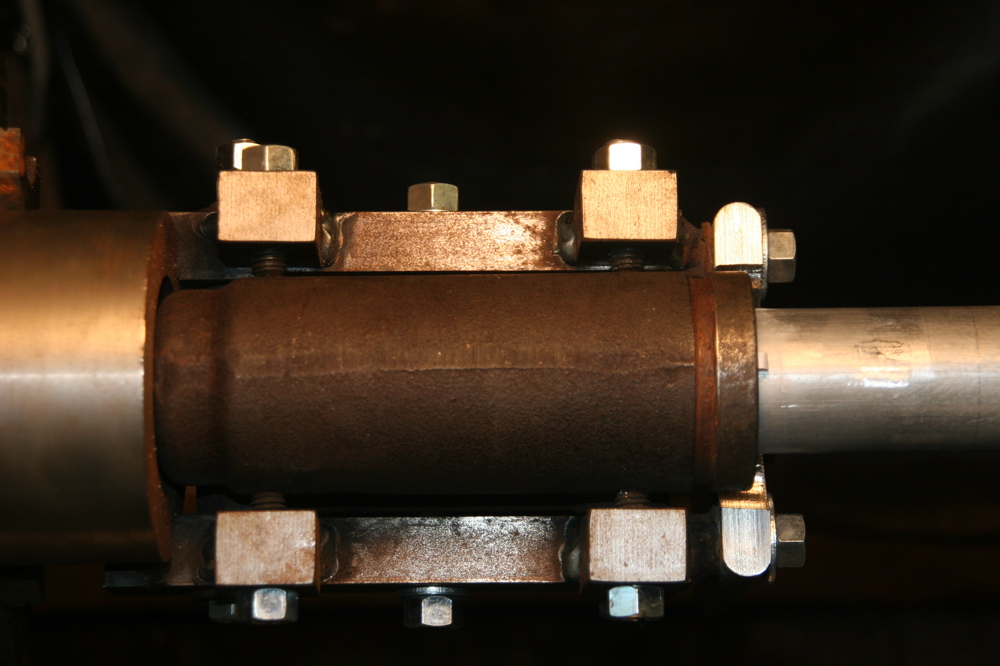

A new master cylinder was not readily available, so the original needed sleeving. This is the boring fixture.

The MC in the fixture. Sleeve made from bar stock by way of McMasterCarr. Rough ID, finished OD. The install mandrel to the right. The short piece fits through the middle of the large diameter of the fixture, so the press bears on the casting.

Centering the bore on the Warner Swasey #3. A dial indicator (absent) bears on the bar stock to measure hop, runout, etc.

Detail of set screws.

Side view.

No turning back now. (A real knee-slapper).

Can I have that with ‘sprinkles’?

“Oooh, shiny…”

If I had to pay myself for the hours involved with this part of the project, I could have purchased a running loader with the total.

I have since found a good source for sleeving in California (his name eludes me at the moment). I’m not going to do the wheel cylinders myself, when I get to that stage.