Sooner or later you find yourself wanting a log out of reach of the tractor.

Solution: Winch.

On a budget, (as usual), this means scrounging. When you can’t find what you need in your own backyard, canvass the neighborhood.

Robert Frost once wrote “Good fences make good neighbors”. To which I’ll add “Good neighbors often have good ‘speculative inventory’ in their fence rows.”

Like, for instance, this chunk of iron: Free for the fixing, with the understanding that it will be available for use if needed.

This appears to be an ‘afternoon job’ done with a cutting torch and underpowered buzz-box. Not bad on the overall layout, but I’d like to smooth off a few rough spots.

It needs a butt plate. Seems like a good place for some Fisher parts. That tailgate is ‘Job Rated’, don’t you know…

Eyeballing the possibilities.

This, over here, has to fit in that, over there.

Glued together.

Lower lift brackets. I think these were a set of trailer spring equalizer pivot mounts…

Welded in place.

Note upper butt plate bracing.

Back to the Fisher parts bin for the chain racks.

Part 1.

Part 2.

Installed.

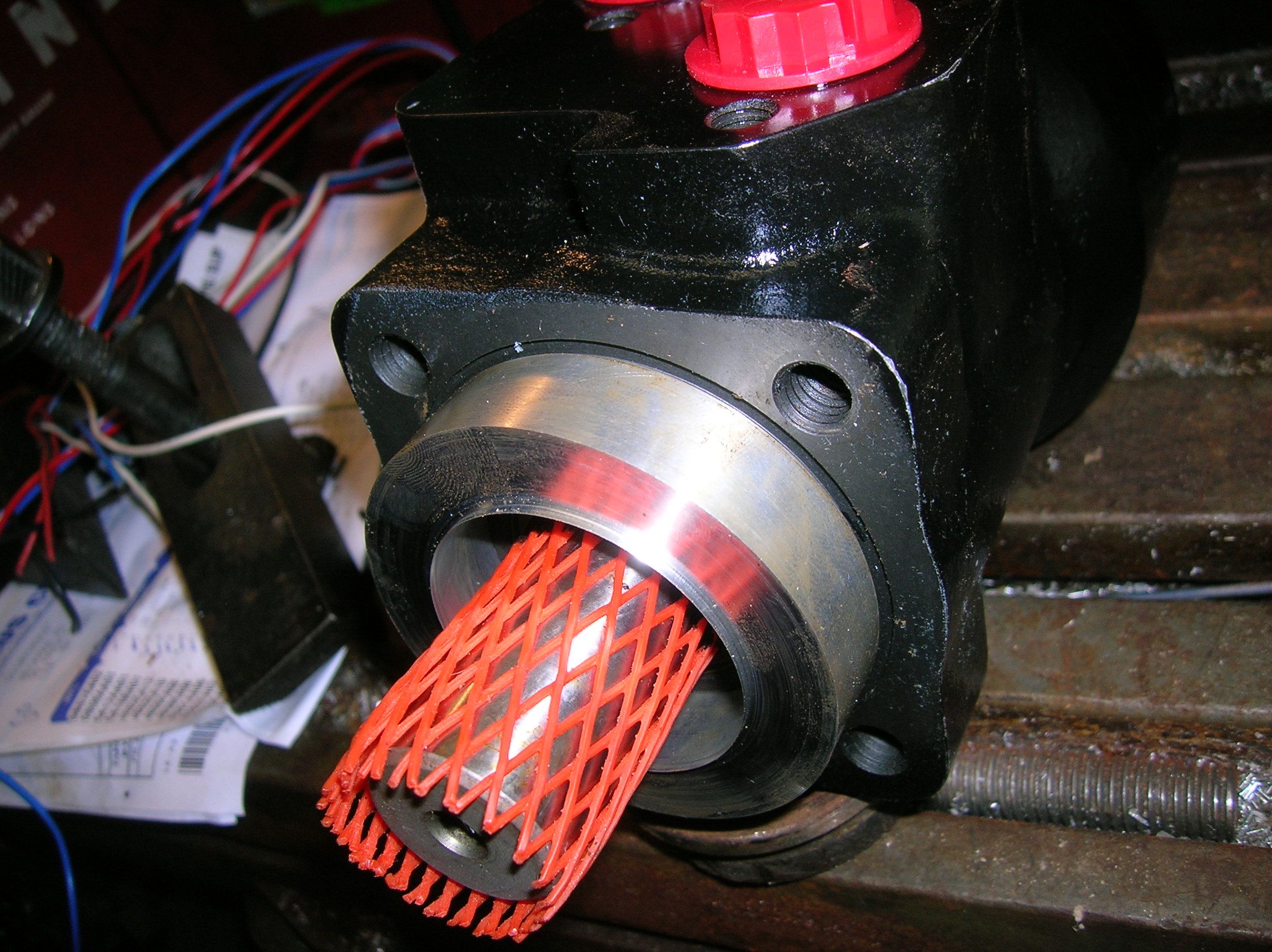

The original drive motor was actually a hydraulic gear pump, probably from a Cletrac crawler. This motor was available from Surplus Center for short money. The average smaller tractor puts out around 10gpm through the remotes, and this motor turns right around 1000rpm with that flow. And that’s about all the worm drive can handle.

The motor flange pilot ring is too small, so I turned a centering spacer out of aluminum.

This will remain once the motor is bolted in place, primarily because there’s no good way to get it back out.

Uni-strut kickstand.

Upper 3point bracket. I took measures off a neighbor’s Farmi and copied the bracket layout.

The cable winder-minder.

It’s slow, but a slow winch is better than no winch.