At the moment, I don’t have discharge conveyors set up for either the processor or the small splitter. While I have parts and a plan, it’s not a priority, as both machines can be moved without difficulty when the piles get too big.

My mode of operation calls for production in the springtime, and delivery in October.

So far, I have been fortunate to have the use of a Bobcat S185 for loading.

A skid steer is effective, but the toothed GP bucket tends to gradually push gravel etc. into the splits, so by the time I get to the back of the bulk pile, I’m loading a bunch of grit on the truck, along with the wood.

Though I get compliments year after year on the burning characteristics, the grit inclusion is not acceptable for a quality product.

This past season, October brought rain, and I was driving around in churned up cake frosting.

At some point, I need my own means, as borrowing machinery is not a good idea for the long term.

So here is the plan:

The rock bucket (Thanks Mr. Newmark et al,) should resolve the greater part of the dirt problem. I will probably build a pair of grapple jaws to make the bucket more versatile for moving brush etc.

The bucket can be used on either the Bobcat, or with this:

(5/26/12 Here we go again…)

This is a Ford 545 industrial with a stuck motor. The loader frame has been removed to facilitate engine repair.

Optimism only gets one so far. The tractor had a glasspack stack, and it was obvious that rainwater could run into the upper end of the muffler, despite the rain flapper.

Uh oh. An exhaust port with fresh water.

I expected a bit of this.

But not this. This tractor sat for a long time, and it appears that water in this cylinder froze, punching a hole through the side.

Diesel cavitation has got nothing on ice.

Fortunately, the three cylinder 201 diesel is common to a number of machines, so it shouldn’t be too hard to find a replacement. I hear tell there is a good block available in yonder village…

I figure any problem that can be solved with either time, or money, really isn’t a problem.

October is a ways off, so the thing to do is pull the motor and see what the rotating parts look like.

(6/6/12) Curiosity and the possibility of a good used block prompts some tractor time.

This would be a piece of cake on a concrete floor, but I’m working in a swamp. It has been raining on an off for 4 days now.

“Call the roller of big cigars, the muscular one, and bid him whip in driveway mud repetitious ruts…”

I’m doing this the easy way.

Pulling muscles from the shell…

I think this block weighs more than a Prius. The clutch appears to have only a few hours use. That green thing is the 10 ton “Jesus Jack”. The previous owner gave it that name, as when anyone first took notice, they exclaimed, “Jesus, that’s a big jack!”.

Snapped back together. If I need yard space in the interim, I can roll it out of the way.

Heavy stand for a heavy motor. I built this years ago for overhauling the 460 in the F350.

As it turns out, I will need to make some sort of adapter plate for the 201.

With the exception of water damage, the inside is very clean. Notice all the timing marks line up. What are the odds a motor would seize like that?

As the block is junk, I chased it around on the floor until there was nothing left to disassemble.

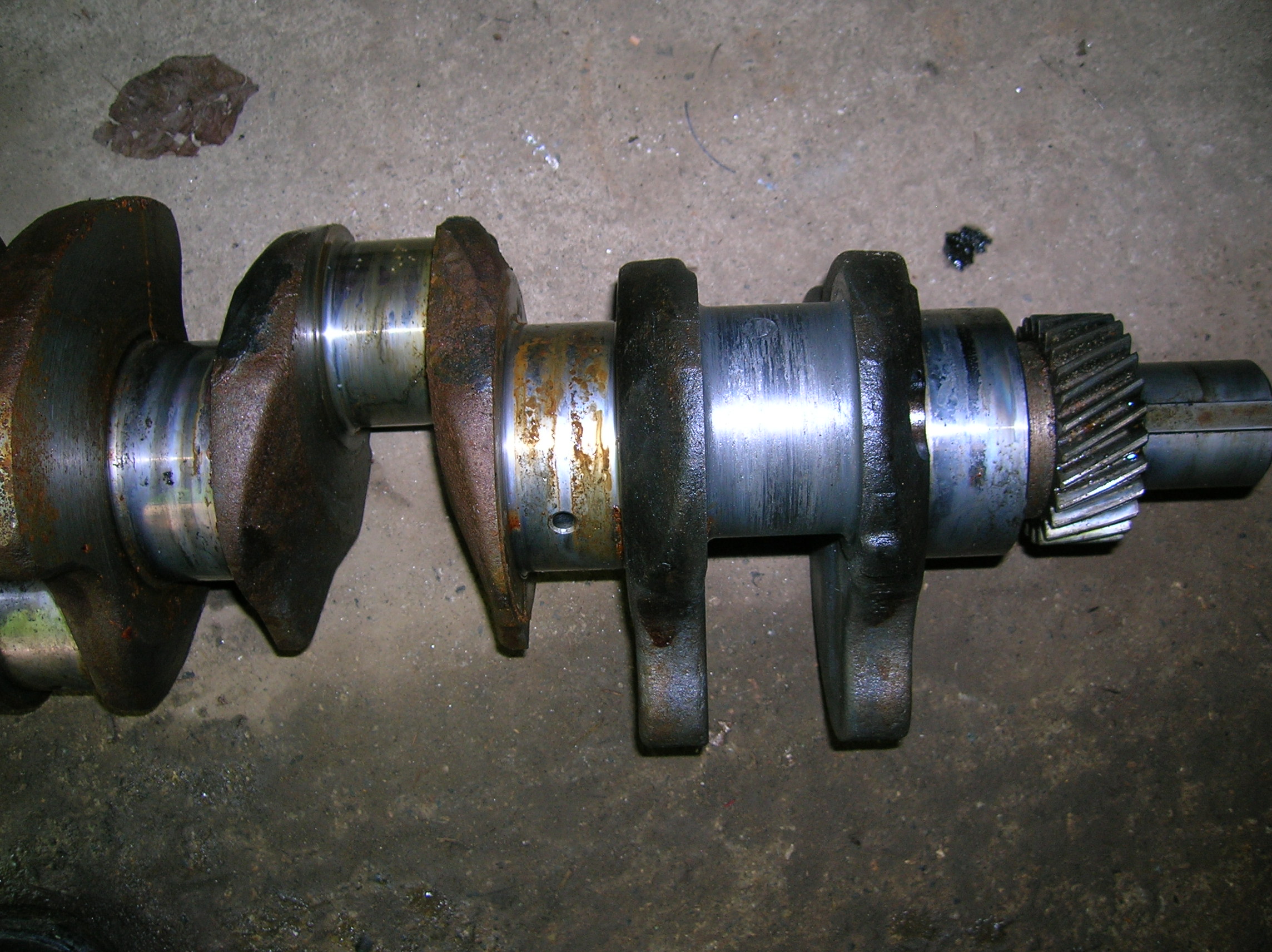

The #1 rod bearing was oil starved, but it looks like the crank may still be usable with a grind. This was confirmed today (6/7/12) with a trip to the machine shop. The gnawed journal is only .003 undersize. I should have a workable estimate in a few days time.

The pistons came out with a sledge and large drift. I aimed for the pin bosses to avoid damaging the rods.

#1 is in front. Notice the smeared bearing material.

Apparently I got ‘lucky’ with this engine, as only the block is beyond repair.

Another view of the hole in the cylinder wall.